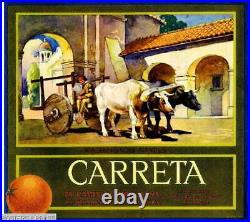

BRAND NEW STUNNING ART PRINT POSTER, GREAT AS A GIFT, SOUVENIR, DECOR OR FOR COLLECTION! CHOOSE THE SIZE YOU WANT. 40×30 cm / around 16×12 inches. 60×45 cm / around 24×18 inches. 80×60 cm / around 32×24 inches. 90×60 cm / around 36×24 inches. 120×90 cm / around 47×35 inches – made of 2 sections. 160×120 cm / around 63×47 inches – made of 2 sections. POSTER comes with a SINGLE-SIDE LAMINATION for. The item “306204 Claremont Los Angeles County Carreta Orange Fruit Crate PRINT POSTER CA” is in sale since Saturday, April 25, 2020. This item is in the category “Home & Garden\Home Décor\Posters & Prints”. The seller is “almaka-5″ and is located in SH. This item can be shipped worldwide.

- Brand: Unbranded

- Original/Reproduction: Reproduction

- Date of Creation: 2000-Now

- Type: Poster

- Features: Laminated

- Material: Vinyl

- Subject: Abstract

- Style: Pop Art

- Color: Multi-Color