Cement is a key ingredient in concrete, playing a crucial role in construction. One of the most important properties of cement is its fineness, which refers to the ptopic size distribution. The finer the cement, the greater its surface area, leading to faster hydration and higher strength development.

Understanding the fineness of cement is essential for ensuring durability, workability, and overall performance in construction projects. In this topic, we will discuss what fineness of cement is, how it is measured, and its impact on concrete properties.

What Is Fineness of Cement?

Fineness of cement refers to the ptopic size of cement powder. It is measured by the percentage of cement ptopics that pass through a specific sieve or by determining its surface area per unit weight.

Cement is ground into a fine powder to increase its reactivity with water, which affects its setting time, strength, and durability. The finer the cement, the faster it reacts with water, improving early strength development.

Why Is Fineness Important?

-

Influences hydration rate and strength gain.

-

Affects workability of concrete mixtures.

-

Improves bonding with aggregates.

-

Reduces permeability, enhancing durability.

How Is Fineness of Cement Measured?

There are two standard methods to determine the fineness of cement:

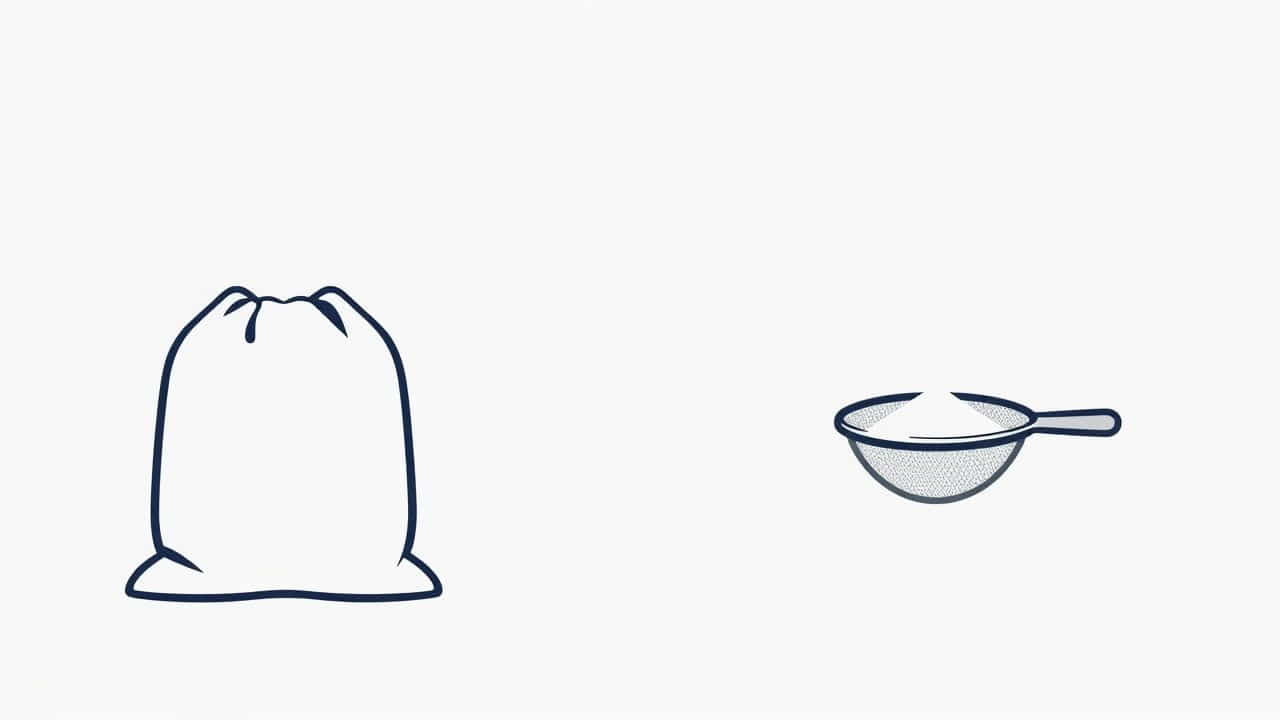

1. Sieve Test (90 Micron Sieve Method)

This is a simple and commonly used method to measure cement fineness. It involves:

-

Weighing 100 grams of cement.

-

Passing it through a 90-micron IS sieve.

-

Measuring the residue left on the sieve.

-

The percentage of retained ptopics indicates the coarseness of the cement.

Standard Requirement:

- For Ordinary Portland Cement (OPC), residue should not exceed 10%.

2. Blaine’s Air Permeability Test

This method measures the surface area of cement ptopics per unit weight (m²/kg). The greater the surface area, the finer the cement.

Procedure:

-

A sample of cement is placed in the Blaine apparatus.

-

Air permeability is tested to calculate specific surface area.

-

Higher permeability means finer cement ptopics.

Typical Values:

-

OPC: 225-400 m²/kg

-

Higher fineness means faster setting and higher early strength.

Other Advanced Methods

-

Laser Diffraction Method – Provides precise ptopic size distribution.

-

Sedimentation Method – Determines fineness by measuring settling time in a liquid medium.

Effects of Fineness on Cement Properties

1. Strength Development

-

Finer cement hydrates faster, leading to higher early strength.

-

Too fine cement may cause excessive shrinkage and cracking.

2. Setting Time

-

Higher fineness reduces initial setting time, making cement set faster.

-

If too fine, workability decreases, making it difficult to handle.

3. Heat of Hydration

- Finer cement generates more heat during hydration, which may lead to thermal cracks in large structures.

4. Workability of Concrete

-

Coarse cement makes concrete harsh and difficult to mix.

-

Fine cement improves cohesiveness, but too much fineness reduces slump.

5. Durability and Permeability

-

Finer cement reduces porosity, making concrete denser and more durable.

-

Helps in waterproofing structures by minimizing water penetration.

Ideal Fineness for Different Types of Cement

| Type of Cement | Fineness (m²/kg) | Application |

|---|---|---|

| OPC 33 | 225-300 | General construction |

| OPC 43 | 300-350 | Structural work |

| OPC 53 | 350-400 | High-strength concrete |

| PPC (Portland Pozzolana Cement) | 300-400 | Durability-focused projects |

| Rapid Hardening Cement | 350-450 | Fast-track construction |

How to Improve Cement Fineness?

1. Improve Grinding Techniques

-

Using ball mills and vertical roller mills enhances cement fineness.

-

Fine grinding reduces unreacted cement, improving strength.

2. Use High-Quality Clinker

- Clinker with optimum composition results in better grinding efficiency.

3. Control the Gypsum Content

- Gypsum regulates setting time, ensuring cement does not set too quickly.

4. Optimize Air Separator Efficiency

- Modern separators control ptopic size, maintaining consistent fineness.

5. Avoid Over-Grinding

- Excessively fine cement may cause high water demand and affect workability.

Common Problems Due to Improper Fineness

1. Too Coarse Cement

-

Slower strength gain

-

Higher permeability leading to durability issues

-

Poor bonding with aggregates

2. Too Fine Cement

-

Fast setting causing workability issues

-

Higher shrinkage leading to cracks

-

Increased water demand reducing slump

The fineness of cement is a critical factor in determining the strength, setting time, and durability of concrete. Properly ground cement improves hydration efficiency, enhancing both early and long-term performance.

By using standard testing methods like the sieve test and Blaine’s air permeability test, manufacturers and engineers can ensure that cement meets quality standards for different construction applications.

For high-performance concrete, maintaining an optimal fineness level is essential to achieve durability, strength, and efficient workability.